Titanium Powder Market is Expected to Grow USD 6.8 Billion by 2035, Driven by Aerospace & Additive Manufacturing | FMI

UK titanium powder market grows at 14.1% CAGR, driven by aerospace, defense, and biomedical demand, boosting additive manufacturing adoption.

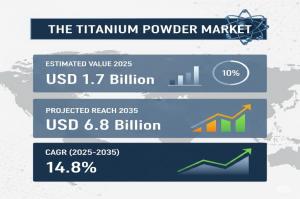

NEWARK, DE, UNITED STATES, August 20, 2025 /EINPresswire.com/ -- The global Titanium Powder Market is on the brink of a transformational decade, forecasted to grow from USD 1.7 billion in 2025 to USD 6.8 billion by 2035, advancing at a robust CAGR of 14.8%. The surge is underpinned by cost reductions from plasma atomization, expanded recycling of aerospace-grade scrap, and growing adoption across aerospace, defense, medical, and automotive sectors. For manufacturers seeking high-performance, lightweight, and corrosion-resistant materials, titanium powder represents a pivotal enabler of next-generation engineering and design.

A Market Redefined by Performance and Scale

Titanium powder’s unique properties—exceptional strength-to-weight ratio, biocompatibility, and resilience under extreme conditions—are placing it at the center of innovation. In 2025, the leading product segment, alloyed powders, will represent 54.6% of the market share, driven by their tensile strength, fatigue resistance, and compatibility with additive manufacturing.

Equally dominant is Grade 5 titanium powder (Ti-6Al-4V), projected to hold 47.3% of revenue share in 2025, reflecting its role as the material of choice for aerospace structures, medical implants, and high-performance automotive components.

With aerospace and defense consuming 52.1% of market revenue in 2025, titanium powder is a critical supply chain material for turbine parts, structural assemblies, and mission-critical defense hardware. Other applications are steadily expanding: automotive (20–25%), medical (15%), industrial and petrochemical (10%), and consumer electronics (5–8%)**, highlighting its versatile adoption across industries.

Why Manufacturers Are Turning to Titanium Powder

The industry’s shift toward additive manufacturing has amplified titanium powder’s importance. Manufacturers can now produce near-net-shape parts using powder bed fusion and directed energy deposition, dramatically reducing waste while shortening lead times. For OEMs and tier suppliers, titanium powder is the solution to:

• Achieving lightweight durability for aerospace structures and automotive parts.

• Meeting biocompatibility demands in customized implants and surgical devices.

• Ensuring corrosion resistance for petrochemical and marine equipment.

• Streamlining logistics by enabling on-demand, localized manufacturing.

Additionally, sustainability strategies are aligning with titanium powder’s recyclability and lower material wastage. As circular supply chains gain traction, regional recycling partnerships and powder-as-a-service models are emerging, offering manufacturers cost predictability, quality assurance, and traceable feedstock.

Geographic Outlook: Fastest Growth in BRICS and OECD Nations

The titanium powder market is not evenly distributed—its growth is being shaped by regional strengths and investments:

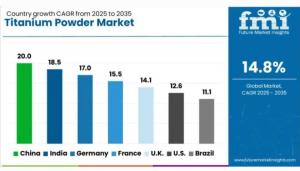

• China is the fastest-growing market, with a 20.0% CAGR, driven by domestic aerospace-grade production and advanced 3D printing adoption.

• India follows at 18.5% CAGR, fueled by orthopedic implants, defense-grade parts, and standardized atomization technologies.

• Germany records 17.0% CAGR, with titanium usage accelerating in automotive turbo systems, industrial turbines, and additive manufacturing hubs.

• France (15.5%) and the United Kingdom (14.1%) continue to scale adoption in aerospace, maritime, and biomedical applications.

For global manufacturers, these regional markets highlight not only demand growth but also opportunities for partnerships and localized supply chains.

Competitive Landscape: Tiered Innovation and Alliances

The market is shaped by Tier 1, Tier 2, and Tier 3 suppliers:

• Tier 1 leaders—such as AP&C, Sandvik, Praxair S.T. Technology, Kymera International, and Tronox Inc.—offer vertically integrated, high-purity powders optimized for aerospace and defense. Their investments in spherical powder production for laser and electron beam fusion systems set industry benchmarks.

• Tier 2 suppliers focus on industrial and automotive adoption, delivering cost-effective powders for MIM, thermal spraying, and tooling applications.

• Tier 3 participants serve niche markets, R&D labs, and prototyping environments, often acting as entry points for smaller manufacturers.

Recent developments underscore the market’s momentum: On June 19, 2024, PyroGenesis Canada Inc. secured its second titanium powder order from a Spanish aerospace client for its NexGen™ plasma atomization system—a step toward long-term supply contracts.

Challenges Ahead: Cost and Handling

Despite strong demand, titanium powder adoption faces constraints. Its production remains energy-intensive, with atomization, clean-room conditions, and alloying driving up costs. Storage requires inert environments, and recycling efficiency is often limited by contamination risks. For cost-sensitive sectors, these factors create barriers to entry.

However, economies of scale, coupled with innovative powder recycling and material-as-a-service models, are steadily reducing costs. Manufacturers that invest early in titanium powder adoption are positioned to capture premium markets while competitors hesitate.

Request Titanium Powder Market Draft Report:

https://www.futuremarketinsights.com/reports/sample/rep-gb-23000

For more on their methodology and market coverage, visit https://www.futuremarketinsights.com/about-us.

Future Outlook: Meeting Manufacturers’ Needs

Looking ahead to 2035, titanium powder’s role will be defined by customization, scalability, and sustainability:

• Customized grades: Manufacturers are increasingly demanding tailored powder chemistries to meet application-specific requirements, particularly in aerospace and medical device manufacturing.

• Material-as-a-service ecosystems: Offering powder sampling, reuse analytics, and replenishment services, these ecosystems lower barriers for new entrants.

• Strategic alliances: Collaborations between powder producers, recyclers, and machine builders will ensure integrated supply chains with closed-loop traceability.

• Expansion in additive manufacturing: As aerospace, defense, and medical device firms push boundaries, titanium powder’s compatibility with advanced 3D printing platforms will define its continued dominance.

Related Insights from Future Market Insights (FMI)

Titanium Tetrachloride (TiCl4) Market - https://www.futuremarketinsights.com/reports/titanium-chloride-market

Titanium Nitride Coating Market - https://www.futuremarketinsights.com/reports/titanium-nitride-coating-market

Titanium Aluminides (TiAl) Market - https://www.futuremarketinsights.com/reports/titanium-alumindes-market

Editor’s Note:

The Titanium Powder Market is gaining momentum with its expanding role in aerospace, automotive, and additive manufacturing. Driven by lightweight strength and corrosion resistance, demand is set to accelerate globally. Innovation in 3D printing and advanced metallurgy will define its future growth trajectory.

Rahul Singh

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.